Power flushing guide

What is a power flush? What are the signs I need a power flush? How much does a power flush cost?

A power flush is the process by which a purpose built machine pumps chemically treated water through your radiators and pipes at high speed in order to clear a build-up of corroded metal and scale. In severe cases the deposits can cause blockages that stop radiators from getting warm, increase fuel bills and damage the boiler.

Power flushing is very effective at cleaning out the system providing it is done using a good quality machine. A power flush takes a day and costs around £450 - £750 depending on the number of radiators (cheaper if undertaken as part of a new boiler installation). In this guide we help you get a good quality power flush, describe the warning signs and show you how to prevent it. For more on system cleaning try our Guide to magnetic filters.

Power flushing guide

What are the signs that you may need a power flush?

There are many signs that your system maybe suffering from a build-up of what the industry refers to as ‘sludge’.

- Cold spots at the bottom of the radiator – sludge and dirt settles at the bottom of the radiators in little piles and as they build up the cold spots get bigger

- The heat transference of the radiators system is reduced

- Radiators stay warm or cool but the pipes are hot

- Radiators need bleeding and the water is noticeably discoloured

- The system makes a banging or knocking sound, this can come from the boiler or radiators/pipes

- Boilers overheat because they have to work extra hard to heat the home

- Boilers can ‘whistle’ as parts of it overheat or cycle on and off as the overheat stat continually cuts in

- For combi boilers you may notice only warm water from the taps as the heat exchanger become blocked on the system side by dislodged debris

What will happen if the problems go untreated?

Leaving the problem will make it worse in many ways:

- The system will become increasingly inefficient and expensive to run

- The radiators will struggle to heat the home

- Loose debris will damage ‘wet’ parts of the boiler

- On combi boilers, hot water will come through warm as the heat exchanger blocks

- Corrosion in the system will lead to pin holes in radiators and very dirty leaks onto carpets

- Radiators and pipework may require wholesale replacement

What about a chemical cleanse/radiator flush or magnetic filter instead?

Power flushing is expensive (£450 - £750 depending on the number of radiators) and we naturally question the need for it. In mild cases of sludge it is possible to add a chemical to the system to breakdown the build-up of dirt. This is often referred to as a chemical cleanse or a radiator flush. This can be left for days or hours (depending on the strength of the chemical) and then drained down and refilled with clean water and inhibitor (to prevent further corrosion).

Equally a magnetic filter can assist with loose debris in milder cases. In severe cases however only a power flush is capable of dislodging debris from the system and removing it. The high cost will save you money long term in both energy savings and paying for future mechanical failures on the boiler and system.

My boiler insurer says I need a power flush

It is very common for the terms and conditions of Boiler Cover providers to stipulate that they will not replace parts damaged by sludge until you have had a power flush. A very common repair is a blocked heat exchanger. It is possible for you to source your own power flush, however the insurer will often want you to use their services.

Check with the insurer that you can use a third party and ask what their criteria is. It is likely that they will require you to use someone that can demonstrate compliance, i.e. they have undergone training with the power flush machine manufacturer, they own a good quality machine and they can provide you with a meaningful certificate that the insurer will accept. Use our Top Tips to booking a good quality power flush to find an appropriately trained provider but check with your insurer first.

Top Tips for booking genuine & good quality power flush

- Look for a heating engineer that has invested in a good quality power flush machine. The power flush machine is the key to a good job. It also shows that the engineer takes their work seriously. The power flush machines below are the main brands available and cost upwards of £1,000. If an engineer has invested in one of these machines they are likely to be committed to providing a great service.

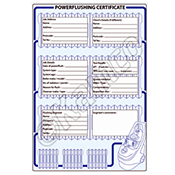

- Ask for a certificate. Machine manufacturers often provide branded certificates for engineers to issue. This will be important if your insurer has asked you to have a power flush.

- Make sure they plan to spend the day at your house. This is very important, because power flushing must be executed correctly in order to work. It is quite laborious and not a procedure that can be plugged in and left.

- Check if the engineer has undergone training with the machine’s manufacturer. The better quality power flush machine manufacturers provide training for their products. Attendance shows that the engineer knows what they are doing and has been trained in good practices.

Look out for engineers that use good quality equipment

Our top tips (above) are to check the machine, the training and the availability of a certificate. We have pulled together some of the better power flush machine brands below (costs are around £1,000 upwards) to help you find an engineer that has invested in this service.

| Product | Kamco | Norstrom Proflush | Fernox Powerflow | Example certificate |

|---|---|---|---|---|

|

|

|

|

|

| Profile | High quality machine with many add on features such as hot flushing and magnetic filters. Kamco provide training and certificates | High quality machine with hot flushing and magnetic filter options | High quality machine but no add on options | Sample power flush certificate (Kamco) |

Can a power flush cause leaks?

The short answer is no, a power flush does not cause leaks. The water is pumped through at high speed but low pressure (2 bar) and this in itself will not cause leaks. However, if significant corrosion has occurred then the radiator may be close 'springing a leak. The removal of debris during a power flush can expose a potential leak, but the best time for this to happen is with an engineer is on site and dust sheets down. A leak at any other time will spill black water onto your carpets.

Can you power flush a combi boiler?

For a new combi boiler it is best to power flush the system before installing the boiler, otherwise the power flush will push debris through the new boiler. On an existing boiler it is best to include the boiler in the power flush as it will clean out any debris that has found its way into the component parts of the boiler.

Can you power flush a micorbore system?

Microbore pipework is very small, 8 – 10mm thick, which makes power flushing more tricky, but not impossible. The machine manufacturers advise engineers to change any twin entry valves to conventional valves (they can remain on the system after the flush) and to do a chemical cleanse before the power flush to break down the hardened deposits as much as possible before the main flush.

Cleaning and prevention tips

Prevention is always better than treatment and there are a couple of proven methods. Across the heating industry some engineers are moving away from chemical treatments to non-chemical methods that are tried and tested in Europe. We detail them here:

British Standard 7593 (BS7593) - Magnetic filter + chemical inhibitor

This new British Standard came into force last years and requires a magnetic filter and chemical inhibitor with all new boiler installations. The water should be tested every five years and adjusted if necessary. Inhibitor is a chemical that prevents corrosion and must be present in every system.

ADI 2035 Directive - Deaerator + demineralised water

ADI 2035 sets out the technical standards for heating water in Germany. A deaerator is a devise about the same size as a magnetic filter that removes air from a heating system. Air in heating system water causes corrosion and many feel that, unlike magnetic filters, this treats the cause and not the symptom. Demineralising methods remove the ions out of water and reduces it conductivity. Corrosion is greatly reduced if the heating water is not conductive.

Whilst there are many benefits to ADI 2035 some boiler manufacturers will state that their warranty is invalidated if this method is used instead of BS 7593. However the same manufacturers do permit this with their boilers elsewhere in Europe.